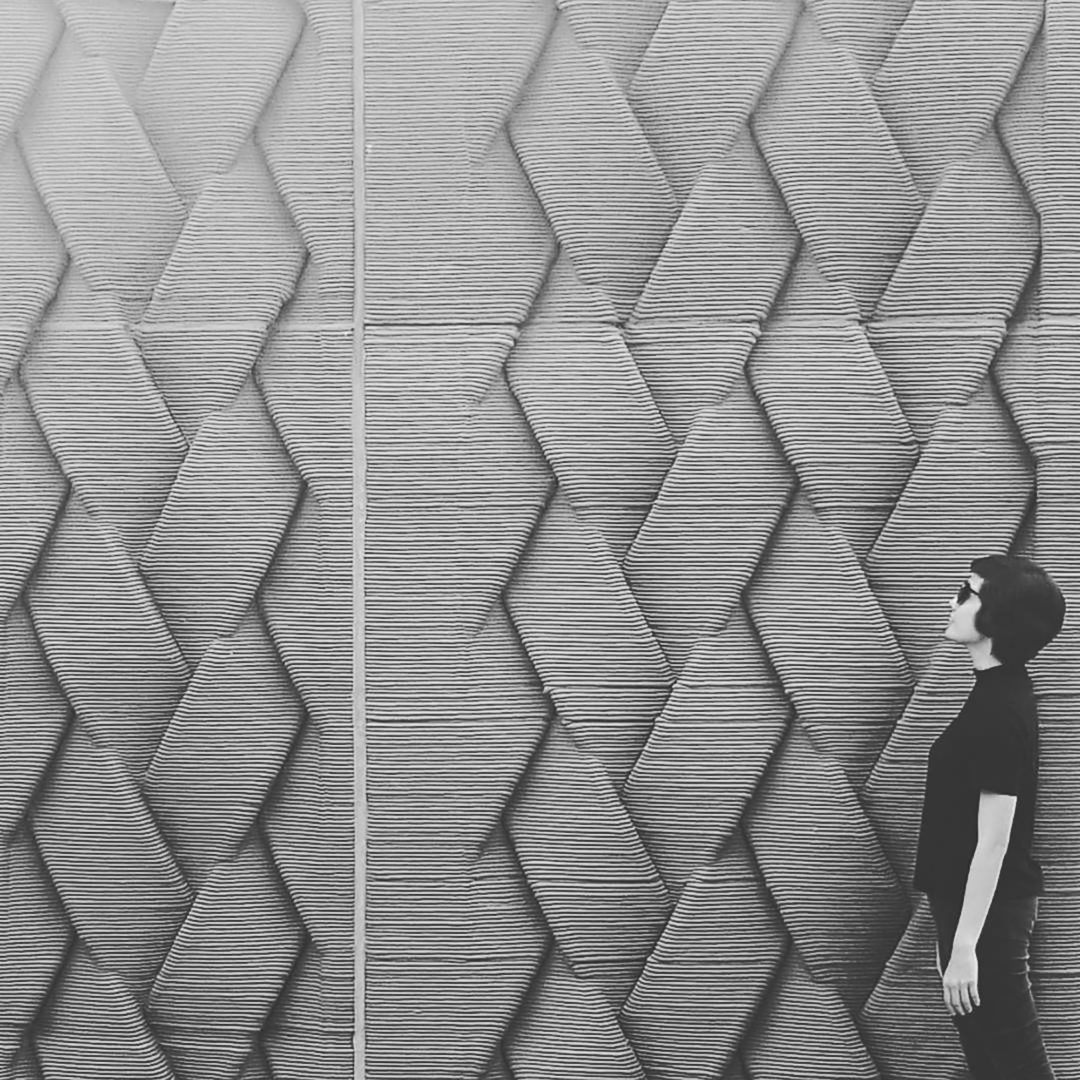

Thailand-based cement manufacturer Siam Research and Innovation Company (SRIC) has been developing innovative building materials, which are leading the edge in 3D printing in architecture. In 2017, the company worked on a project titled, Triple S, which is based on traditional Thai craftsmanship to generate surface, structure, and shelter in a single process; its specific artisanal form creating habitable and striking framework for structural purposes, easily building living spaces.

Triple S is a new evolution in 3D printing in which, unlike previous developments, the design and 3D printing technology platforms work side-by-side. The advanced research of printing and materials allows the improvement of other dimensions such as structure, engineering, and architecture.The innovative material is capable of transforming surfaces using an appropriately-sized printing nozzle, making it the most sophisticated design method in architecture in this 3D printing work.

The outer surface layer and the inner truss of the 3D printing objects are included while designing. The inner truss is designed for structural purpose in order to withstand the load. The designed surface can perform in both aesthetic and structural functions. Indeed, texture patterns developed in the Triple “S” have been derived from moving paths on load-bearing concrete structures.

The design concept of Triple “S” is inspired by Thai folk handicraft which goes back around 250 years in Phra Nakhon Si Ayutthaya, the erstwhile Thai capital. The weaving pattern is a fish-shaped ornament made of coconut leaf. The weaving pattern is designed to be modular and implemented in a concrete block. The concrete is designed to be extruded using 3D printing to increase its dimensions as its weaving appearance. After printing, the 3D printing concrete panel is fabricated with the pattern and serves as a structure for holding its weight. Thereafter, the weaving pattern of the final module acts as a truss for structural purposes.

The complexity of cement material technology is applied and incorporates 3D printing technology, along with the full understanding of the mechanism of printer movement allowing for less weight compared to a traditional fabrication unit such as precast. This allows the compressive strength greater than 45 MPa and the flexural strength greater than 80 MPa. Furthermore, it consumes less material since a double structure cladding system used in GRC technology is needed in order to support the weight itself for a more sustainable technique.

Courtesy: Lapyote Prasittisopin, Chanita Chuaysiri, Siam Research and Innovation